2016 Yuhong Barite Powder Raymond Grinder Mill ForBarite Grinding Production Line1. Barite Raymond Grinding Mill Introduction:Barite Raymond grinding mill is used for grinding the barite, limestone, kaolin, cement, slag, etc, below scale 9.3 of Mohs hardness and 280-odd sorts of non-inflammable and nonexclusive stuff in the trades of mining, metallurgical industrial, chemical engineering and building material for high fine powder generation and processing. The product size is adjustable in the range of 80-325 (600 the largest) meshes. It is possible to produce 30-80 mesh coarse powder through special device in the machine.

2.Barite Raymond Grinding Mill Features :1. The whole plant is a vertical structure of strong systematic characteristic, so it occupies small area. From crushing of raw material to grinding and packing is an independent production system.

2. Compared with other milling plants, its passing ratio achieves 99%, this is what other mill can not reach.

3. Driving system of main frame adopts airtight gearing and pulley, drives smoothly and operates reliably.

4. Main parts of the whole plant are made from cast and steel of high quality. The technique is so subtly that insures the durability of whole plant.

5. The electric control system is centralized controlled, so the automaticity is high, no people are needed in the operating room and it's easy maintenance.

3. Barite Raymond Grinding mill Working principle: First the materials are crushed by the jaw crusher,then the crushed materials are transferred to a hopper by the bucket elevator ,fed uniformly.quantltatively and continously by the vibration feeder to the grinding chamber of the main frame for grinding.the grinded particles are brought up by the air current from the blower into the classifier for classification.the particles with the required fineness are brought up by the air current through the pipe into a collector for separation and collection,the finished particles are discharged from a pipe outlet,Because of some moisture contained in the materials to be grinded,the heat resulting from grinding leads to the vaporized air which changes the airflow volume,Moreover,the outside air inhaled from the narrow gaps of the piping connections can increase the volume of air current.Therefor,it is necessary to adjust redundant air pipe between the blower and the main unit for keeping the balance of the air current.Then the redundant air is quided into a cloth bag of a dust cleaner to collect the fine power in the air,Finally, the redundant air is discharged after purfication.

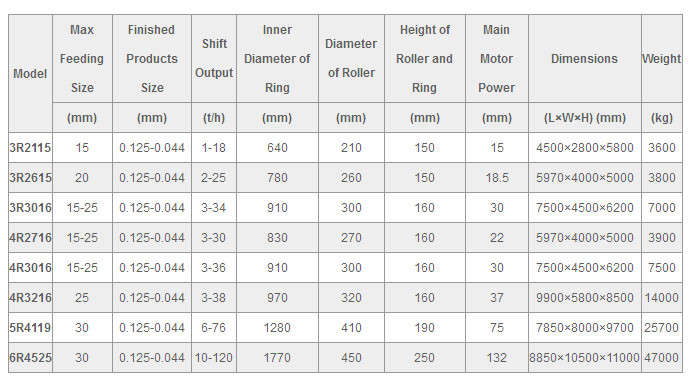

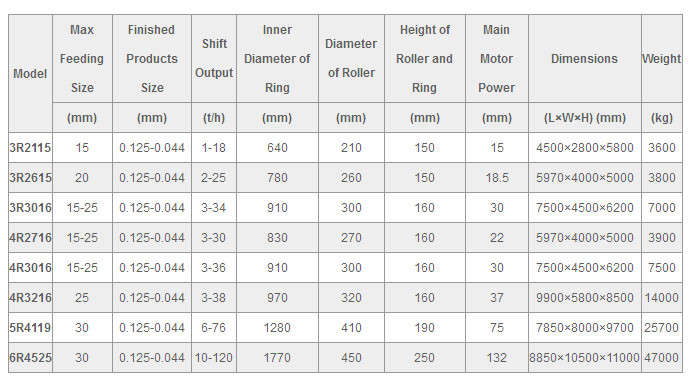

4.Barite Raymond Grinding mill Parameters:

4.Barite Raymond Grinding line :

Company Profile

Company Profile