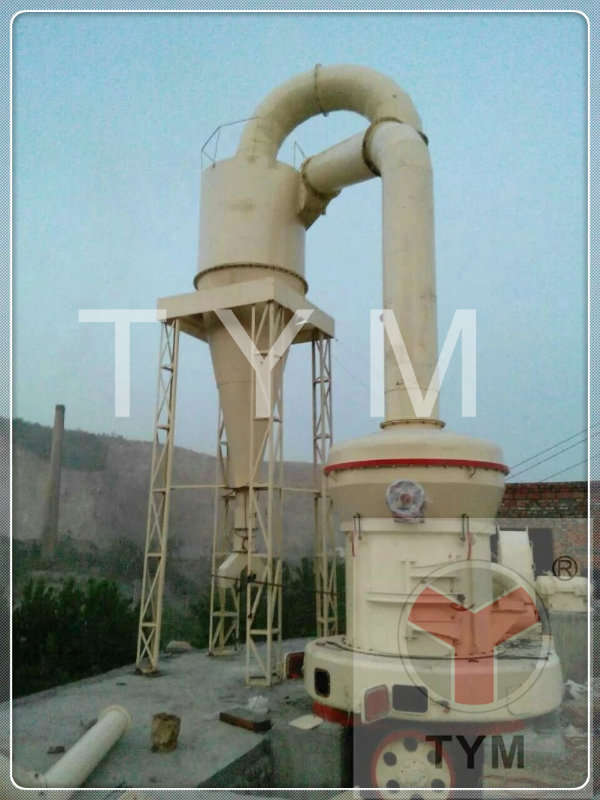

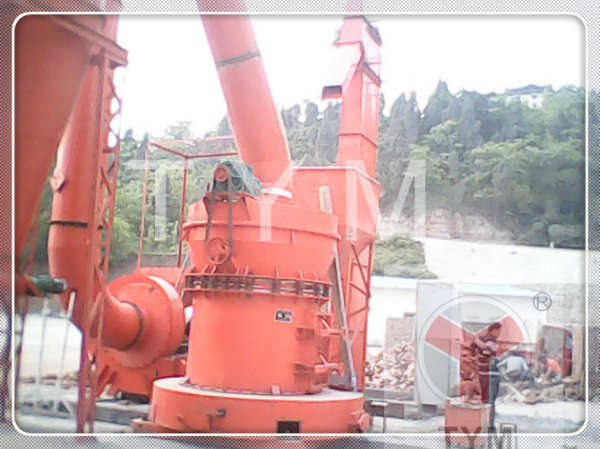

YGM type raymond mill Stone Powder Making Machine

High Pressure Suspension Grinding Mill

Introduction of YGM type raymond mill Stone Powder Making Machine

High Pressure Suspension Grinding mill is a new kind of mill, which is invented with great concentration and on the basis of many years of powder processing experiences. This invention starts an epoch of high efficiency and low cost in international mining industry. High Pressure Suspension Mill can be used to grind non-inflammable and non-explosive materials with Moh's hardness below 9.3 and moisture content below 6%, such as barite, limestone, pottery, scoria. Size of final products can be adjusted between 80-425 mesh (The fineness can reach 1000 mesh). High Pressure Suspension Mill can produce coarse powder between 30-80 mesh by adding special equipment. This machine is widely used in the fields like mining, chemical industry, construction materials, metallurgy, etc.

High Pressure Suspension Grinding Mill Working Principle:

In the mainframe of High Pressure Suspension Mill, there are strong springs with pressure as high as1000-1500 kg equipped on the roller suspender. When High Pressure Suspension Mill works, the roller rotates around the principal axis, and clings to ring under the effect of the strong spring and eccentricity. Its press is 1.2 times of Raymond mill under the same press condition, so the production is largely increased. When the materials are sent into the grinding chamber, they are brought to the space between the roller and ring and get grinded. Then the powder grinded will be blown into separator. The fine powder after departed with the air is discharged through the outlet as final product. The large-sized powder falls back for regrinding. The air will be back to the blower for repetition of the above process. The left air wil come to thel bag filter to get cleaned. When the wear and tear between roller and the ring reaches certain degree, adjust the length of the strong spring, so to keep the invariable pressure between the roller and the ring, to make sure the stable production and the fineness.

High Pressure Suspension Grinding Mill Characteristics:

(1). Compared with other mills, its capacity increases by 10%-20% under the same power condition, and compression force of rollers to material improve 800-1200kgf under the force of high-pressure spring.

(2). Size of final product can be 0.613mm (30mesh) -0.033mm (425mesh). Some can reach the fineness of 0.013mm (1000 mesh).

(3). High Pressure Suspension Mill meets the requirement of national dust-dump standard.

(4). The separator can be adjusted very easily.

(5). The multi-class seals are adopted to keep the grinding equipment tightly closed.

| Model |

Roller |

ring |

power |

Final size (mm) |

otor Power

(KW) |

Capacity

(T/h) |

| No. |

Diameter

(mm) |

Height

(mm) |

Diameter

(mm) |

Height

(mm) |

| YGM65 |

3 |

210 |

150 |

650 |

150 |

15 |

0.613-0.033 |

15 |

0.4-1.8 |

| YGM75 |

3 |

260 |

150 |

780 |

150 |

15 |

0.613-0.033 |

18.5 |

1-3 |

| YGM85 |

3 |

270 |

140 |

830 |

140 |

20 |

0.613-0.033 |

22 |

1.2-4.6 |

| YGM85B |

3 |

270 |

150 |

830 |

150 |

20 |

0.613-0.033 |

22 |

1.2-4.6 |

| YGM95 |

4 |

310 |

170 |

950 |

170 |

25 |

0.613-0.033 |

37 |

2.1-5.6 |

| YGM130 |

5 |

410 |

210 |

1280 |

210 |

30 |

0.95-0.033 |

75 |

3-9.5 |

| YGM160 |

6 |

510 |

230 |

1600 |

230 |

60 |

0.95-0.033 |

185 |

5-22 |

If you are interested in our products,please feel free to contact with me:

Zhengzhou General Mining Machinery Co.,Ltd.

Contact with Ms. Cherry

Tel: 86-371-67971297 Mob: 86-13633718025

Office Add: Zhangzhai Industry Zone,

Zhongyuan Western Road, Zhengzhou, China.

We hope our perfect products and service can satisfy you,and welcome to our factory to visit . Looking forward to building long-term relationship with you !

Service Standards of Our Company

Pre-sale:

(1) Device model choice.

(2) According to customer's special requirements, design and manufacture of products.

(3) Training technical personnel for clients.

(4) The company free of charge to the user on-site engineering and technical personnel planning site for the user to design the best processes and programs.

Sale:

(1) Product acceptance.

(2) To help customers develop construction programs.

After-sale & Warranty:

(1) Quality guarantee period of the machines are one year (12 months from

The dated which the seller's technician install and test the machines qualified) and they are according to the goods standard regulation (industry standard).

(2) During warranty period, the supplier will supply free maintenance, replace the defective parts or components, but except the normal wearing parts.

(3) The seller should send workers to install and adjust the machines, and

Our workers are also responsible for the training of the buyer's workers.

(4) The seller is responsible to provide the buyer operation manual, products list, certificate, (for buyer in Vietnam Customs Clearance) and other relevant equipment information. After the two sides signed the contract, the seller provides foundation drawing of all equipment to buyer.

Company Profile

Company Profile