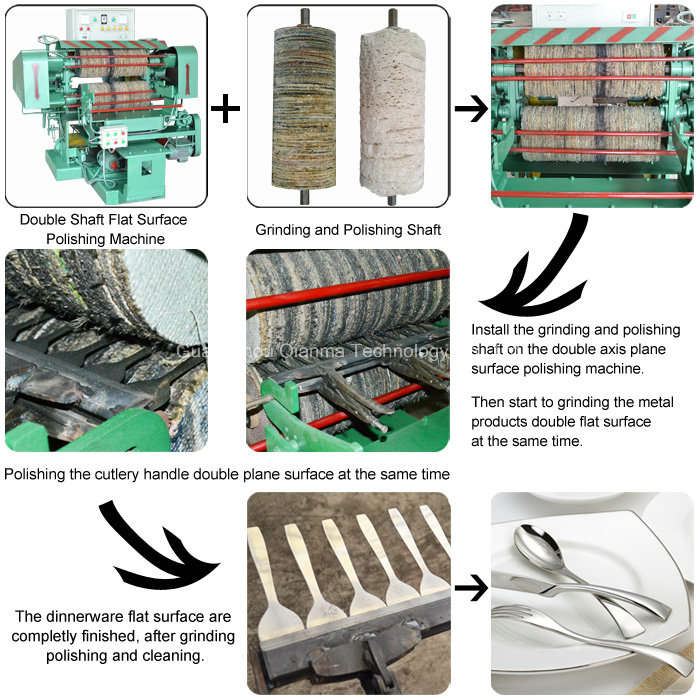

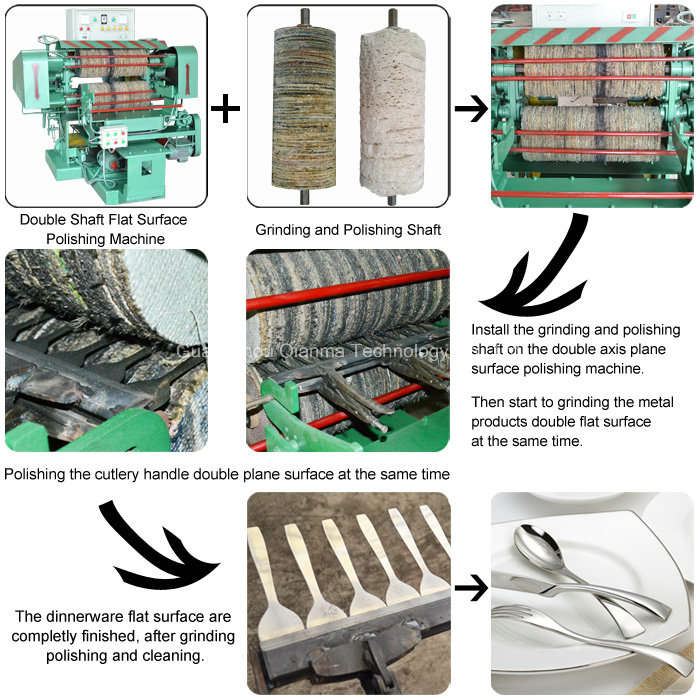

Stainless steel spoon and fork dinnerware plane surface fine mirror effect finish polishing machine

Basic Parameter Of Machine

| Main Shaft (Hexagon) |

Rotate Speed: 1800-2200rpm, Length: 600mm, Adjutsing Range: 600mm |

| Grinding Time |

0-3 minutes |

| Size |

1500mm*1500mm*1300mm (L*W*H) |

| Weight |

1250kg |

| Work Table size |

580mm*40mm (L*W), Up And Down Adjusting Range: 20-30mm |

| In/ Out Travel Distance Of Work Table |

400mm |

| Sway Range Of Work Table |

0-70mm |

About the Main Motor Power:

Power: 5.5KW /7.5KW. (5.5kw is suitable for small size plane work piece polishing; 7.5KW is suitable for the big size flat work piece polishing. If you have any confused to choice the right power, please kindly contact us.)

Voltage: 380V, 3 phase. (Noted: The voltage is measured by industry voltage. Every country is different. So, please inform us your industry voltage. We accept custom-made )

Frequency: 50Hz .

Parameter Of Main Motor

| |

Power Rate |

Rotate Speed(rpm) |

| Main Motor |

4 Poles, 5.5/7.5KW |

1400 |

| Sway Controling Motor |

4 Poles, 250W |

1400 |

| In/Out Controling Motor |

6 Poles, 370W |

980 |

| Open/Close Controling Motor |

4 Poles, 400W |

400 |

About the Grinding Area:

1. Area size (length * wideth ): 600*800mm. Suitable for grinding / polishing the flat work pieces. ( We accept custom-made.)

2. Up and Down Adjusting Range: about 20-30mm.

Application:

It is application to metal/aluminum/copper/brass/zinc/allyoc/stainless steel flat surface matt/satin/mirror/fine effect polishing. It can finish different polishing steps with the automatic flat buffing machine.

Best for flat/plane surface polishing. Such as stainless steel flat, door hinge, mobile phone case and so on.

(If you have any questions on your work pieces, please kindly contact us for inquiry. Our engineer team will support the best service for you.)

Advantage:

1. Easy adjustment. (Only with 6 control button to finish all the operate step! And it can adjust the grinding time according your products. )

2. With high efficient production .It will spend from 30 seconds to 3 minutes to finish one polishing step at one time .

3. More flexible for many kinds of flat products polishing.

Abrasive tools use for the surface polishing machine

First Step: Matt Grinding

deniem buffing wheel + polishing sand+ sanding compound/red polishing wax.

Second Step: Middle polishing comes with slight mirror effect.

Cloth sisal wheel / sisal wheel/ treated sisal wheel + purple polishing compound.

Third step: final effect

1) Fine mirror buffing effect: cloth wheel/ bias airway cloth wheel + green compound.

2) Satin drawing polishing effect: nylon wheel / scortch sponge nylon wheel.

Company Profile

Company Profile