The Ball Spline is a rolling guide spline bearing. It is an innovative product with a ball rolling on a groove connected to the shaft, realizing allowable loads greater than with linear bushing and enabling torque transmission while making linear movements.

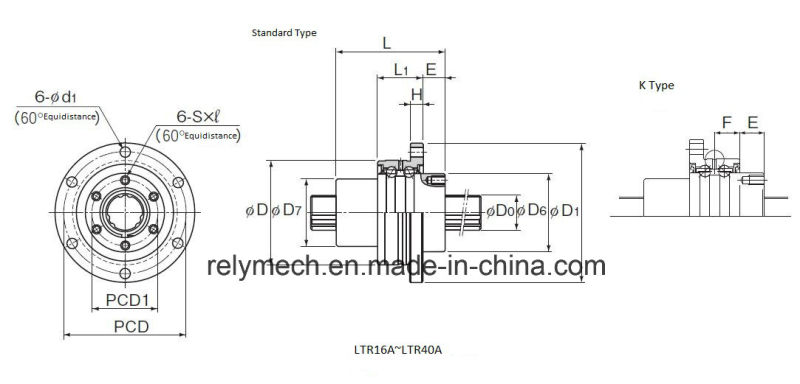

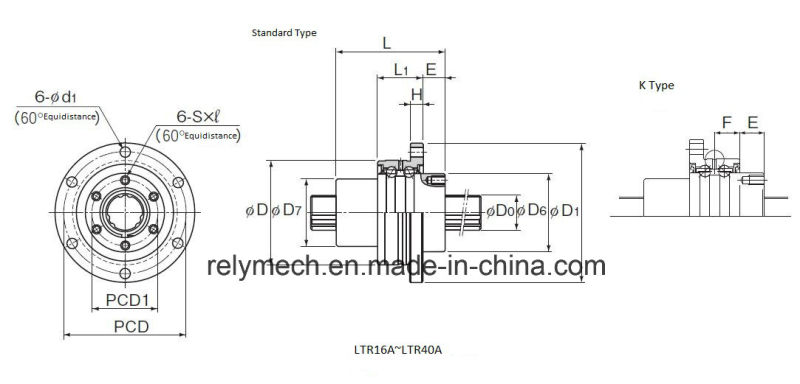

Rotary type-LTR LTR-AThis model is a compact unit type of Ball Spline whose support bearings are directly integrated with the outer surface of the spline nut.

Application:Z axis of scalar robot

Wire winder

Rotary type-LTR8A/LTR10A/LTR16A/LTR20A/LTR25A/LTR32A/LTR40A

| Model No. |

Spline nut dimension |

Shaft

D0

h7 |

Ball

column |

Basic torque rating |

Basic load rating |

Static permissible moment |

Support bearing basic load rating |

Mass |

| Out dia. |

Length |

Flange |

D8

h7 |

D7 |

H |

L1 |

Standard Type E |

K Type |

Oil Hole

F |

E1 |

PCD |

PCD1 |

SXl |

d1 |

| D |

Tolerance |

L |

D1 |

CT

Nm |

C0T

Nm |

C

kN |

C0

kN |

MA

Nm |

C

kN |

C0

kN |

Spline nut

kg |

Shaft

kg/m |

| LTR 8A |

32 |

-0.009

-0.025 |

25 |

44 |

24 |

16 |

3 |

10.5 |

6 |

8.5 |

4 |

3 |

38 |

19 |

M2.6X3 |

3.4 |

8 |

4 |

1.96 |

2.94 |

1.47 |

2.55 |

5.9 |

0.69 |

0.24 |

0.08 |

0.4 |

| LTR 10A |

36 |

33 |

48 |

28 |

21 |

3 |

10.5 |

9 |

11.5 |

4 |

- |

42 |

23 |

M3X4 |

3.4 |

10 |

4 |

3.92 |

7.84 |

2.84 |

4.9 |

15.7 |

0.77 |

0.3 |

0.13 |

0.62 |

| LTR 16A |

48 |

50 |

64 |

36 |

31 |

6 |

21 |

10 |

10 |

10.5 |

- |

56 |

30 |

M4X6 |

4.5 |

16 |

6 |

31.3 |

34.3 |

7.05 |

12.6 |

67.6 |

6.7 |

6.4 |

0.35 |

1.6 |

| LTR 20A |

56 |

-0.010

-0.029 |

63 |

72 |

43.5 |

35 |

6 |

21 |

12 |

12 |

10.5 |

- |

64 |

36 |

M5X8 |

4.5 |

20 |

6 |

56.8 |

55.8 |

10.2 |

17.8 |

118 |

7.4 |

7.8 |

0.51 |

2.5 |

| LTR 25A |

66 |

71 |

86 |

52 |

42 |

7 |

25 |

13 |

13 |

12.5 |

- |

75 |

44 |

M5X8 |

5.5 |

25 |

6 |

105 |

103 |

15.2 |

25.8 |

210 |

9.7 |

10.6 |

0.79 |

3.9 |

| LTR 32A |

78 |

80 |

103 |

63 |

52 |

8 |

25 |

17 |

17 |

12.5 |

- |

89 |

54 |

M6X10 |

6.6 |

32 |

6 |

180 |

157 |

20.5 |

34 |

290 |

10.5 |

12.5 |

1.25 |

5.6 |

| LTR 40A |

100 |

-0.012

-0.034 |

100 |

130 |

79.5 |

64 |

10 |

33 |

20 |

20 |

16.5 |

- |

113 |

68 |

M6X10 |

9 |

40 |

6 |

418 |

377 |

37.8 |

60.4 |

687 |

16.5 |

20.7 |

2.51 |

9.9 |

1. Setting conditions

Stroke length, velocity, magnitude of the applied load, mounting space, operating frequency, required service life, dimension(No. of spline nuts, span), installation direction, environment, accuracy.

2. Selecting a type

High torque type-LBS/LBST/LBF/LBR/LBH

Medium torque type-LT/LF/LT-X

Rotary type-LBG/LBGT/LTR/LTR-A

3. Studying the spline shaft strength

Estimating the spline shaft diameter/length, permissible load on the spling shaft, displacement of the spline shaft(deflection, torsion), method for fixing the spline shaft.

4. Predicting the service life, compared with the required service life.

5. Selecting a preload

6. Determining the accuracy

7. Selection according to the environment

Why Choose us?Over 10 years export expenrience;

Less MOQ;

Competitve Price;

Quick response;

Short Delivery time;

Good service

Provide systematic solution for equipment components.

Relymech Industry Co., Limited, a rapid-developing industrial product distributer located in China, is focusing on equipment components systematic solution for manufacturer & maintenance business in mechanism transmission parts, electrical parts and pneumatic components etc.

Our team has more than 10 years' experience in design, process and sales in this industry. We commit to make continuously improving & innovation to meet customer's requirements and work closely with our partners to provide qualified parts with competitive price and best service to each customer.

Company Profile

Company Profile