Negotiable

The date of payment from buyers deliver within days

Zhejiang

Long-term effective

2017-12-26 10:39

216

Company Profile

Company Profile

By certification [File Integrity]

Contact:Miss Eva Wong(Mr.)

Email:

Telephone:

Phone:

Area:Zhejiang

Address:Zhejiang

Website: http://great1995.artstx.com/

Usage:

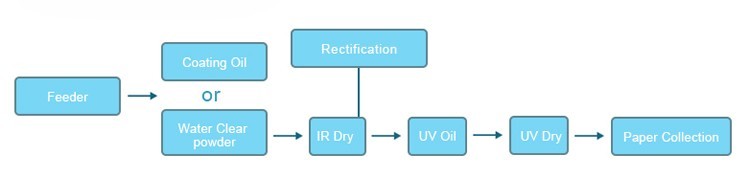

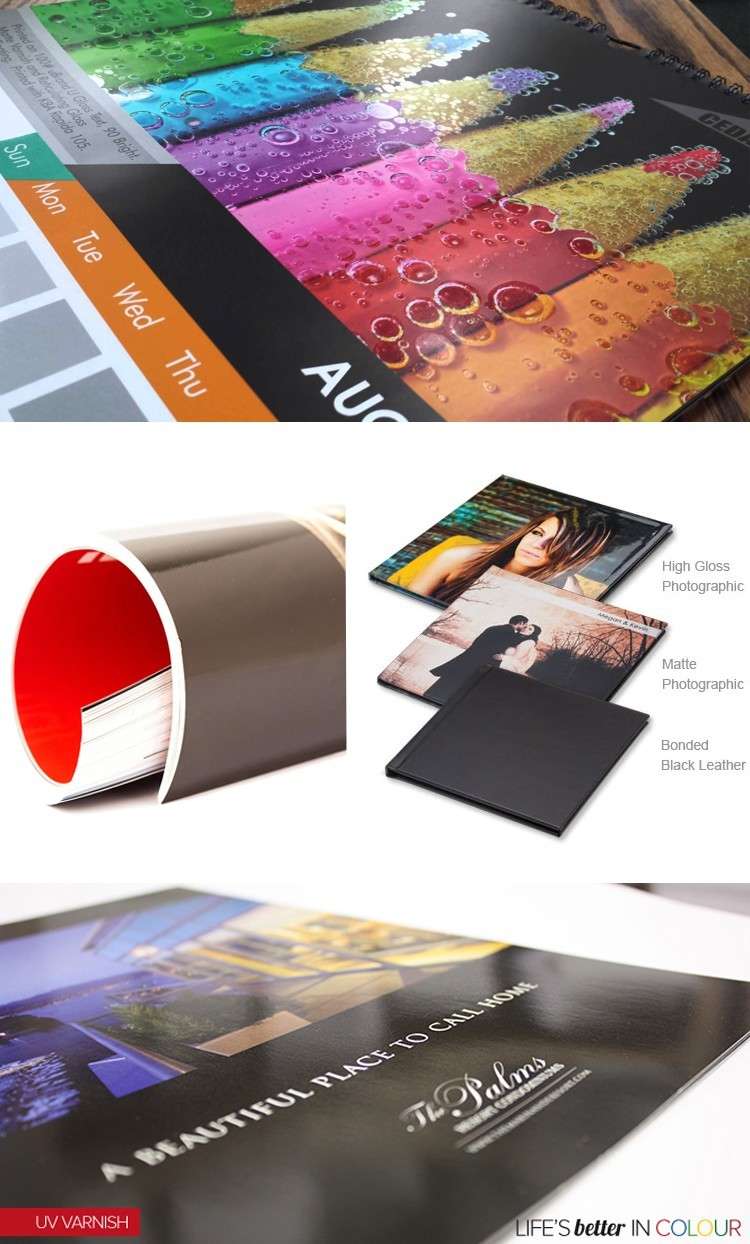

MSGZ-II-1200 Full-Automatic Paper Polishing and Varnishing Machine as a professional equipment used for oil/UV oil coating laminating on the overall surface of paper printed matter. After oil coating machine processing, the printed matter will greatly improve surface gloss, Wear-resisting and waterproof effects. Machine with reasonable structure and easy control, it is suitable various thin and thick paper (80-600g/m2). Widely used in books, magazines, calendars, cards, brochures, packaging boxes, window display drawing surface decoration painting. It is a necessary equipment for the printing factory, packaging factory and decorative painting factory.

Model Optional:

MSGZ-II-1200A with Air-Knife system, for thin and thick-cardboard(80-500g/m2).

MSGZ-II-1200B without Air-Knife system, for thick-cardboard only(250-500g/m2).

Specification For Msgz-II-1200 Semi Automatic Lamination Machine Manufacturer

Model |

MSGZ-II-1200 |

Length of Roller |

1250mm |

Suitable Paper Thickness |

80-500g/m2 |

Working speed |

80m/min |

Power |

380V 50HZ |

Main motor power |

80w |

Infrared Heating power |

22kw |

Ultraviolet heating power |

3×8kw or 2×8kw |

Weight |

8000kg |

Overall Dimensions |

19000×2000×1700mm |

Characteristics:

Single-Unit UV Varnishing Machine, with three-roller coating system to apply UV varnish onto the sheets surface, use a suction conveyor belt to transport the sheets through the UV lamp Dryer and Cooling Fan station, automatic delivery.

Machine parts:

UV Coater

UV Lamp Dryer Conveyor

Options:

Single-Set Dust Cleaner

Dual-Set Dust Cleaner

Air-Conditioner Cooling System

Air Compressor

Processing: More details, pls contact with me feel free!

More details, pls contact with me feel free!

TIME IS GOLD!

WITH US YOUR MONEY IN SAFE!

QUALITY IS OUR CULTURE AND THE SOUL OF OUR ENTERPRISE!

Please read the following questions carefully, thanks!

Question 1:

How can I choose the suitable machine for our product?

Answer:

Pls send the paper size and film type and Target capacity per day. We will suggest the suitable machine to you.

Question 2:

May I get more your company information?

Answer:

Laminating machine factory since from 1995, with more than 20 years producing machinery experience and 12 years exporting experience. Every machine with CE. We could develop together with our customer.

Question 3:

May I get the true best price?

Answer:

Nine Main Factories suppliers direct export through MOSUN EXPORITNG COMPANY, We could provide quality products with the best price, we could supply the most reasonable processing line machinery to our customer in short time.

Question 4:

How about the MOQ?

Answer:

Every machine min order is one set in MOSUN website.

Question 5:

How about the payment term?

Answer:

L/C, TT, Assurance trade through Alibaba, we could discus together.

Question 6:

How long the delivery time?

Answer:

As a manufacture, the normal standard machines have stock, for example:

We could delivery machine in one week after receive the payment!

The customized standard machines will be extended delivery time, if customer upgrade mechanical configuration or change the voltage or choose fully automatic machinery, we will check with you before correct order.

Question 7:

Can we upgrade the configuration of the machine?

Answer:

Actually, the configuration of our machinery are ok. We could depend on customer reminds, change the configuration, for example change the Electrical components, Main Motor Brand, Bering Brand and other parts.

Our long-term partner:

SCHNEIDER, SIEMENS OMRON, LG; NTN/NSK BEARING; ABB MOTOR;

Question 8:

How about the warranty?

Answer:

We are responsible for the quality of each parts. One year defects liability period; Engineers available to service;

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Machines are new (or unused) and the guarantee period will be given thirteen months from shipment date. During this period, the seller will provide free maintenance and free spare parts that caused by the machine's quality, but the buyer must pay the courier cost. Parts damaged because of mishandling and consumable parts are not covered by any warranty.