Negotiable

The date of payment from buyers deliver within days

Guangdong

Long-term effective

2017-12-11 16:24

254

Company Profile

Company Profile

By certification [File Integrity]

Contact:Mr. Williax Wang(Mr.)

Email:

Telephone:

Area:Guangdong

Address:Guangdong

Website: http://morganseals.artstx.com/

Oil seals are also known as rotary shaft seals. They are often called grease, fluid or dirt seals. They close spaces between stationary and moving components in mechanical equipment. They are used to help prevent lubricant escape. Oil seals stop harmful contaminants from entering machinery, particularly in severe environments. They are vital components of almost every type of machine and vehicle in operation. They protect all types of precision-constructed, close-fitting ball, sleeve and roller bearings.

Oil seals help prevent lubricants from escaping the bearings or a specific area in precision bearings.

In machine components, oil seals help prevent abrasives, corrosive moisture and other harmful contaminants from entering machinery. They also help stop mixture of two different mediums such as lubricating oil and water.

Rotary Shaft seals are produced by vulcanising an elastomer to a metal ring. This acts as a stiffener, and utilises a metal tensioning spring behind the sealing lip. Many other designs can be supplied. These include, High Pressure, Dual Spring and end caps. The most common elastomer used is Nitrile.

The seals conform to DIN 3760. Rubber types available are Nitrile, Viton ®, Silicone and EPDM.

The seals are used in a full range of equipment in the following industries:

• Automotive.

• Manufacturing.

• Off-highway.

• Oil refineries.

• Power transmission.

Example applications include:

• Industrial Pumps.

• Electric Motors.

• Compressors & Vacuum Pumps.

• Engine Seals.

• Agricultural Machinery Seals.

• Domestic Appliances

Lip Material

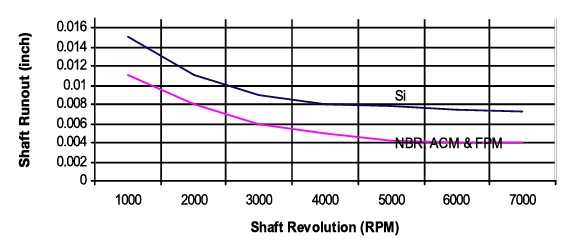

It is very important to take into account the environment in which the seal will operate when you are selecting the sealing element material. The most important factors are temperature, medium being sealed, pressure, and shaft speed.

| Media | Maximum temperature, depending on the materials | |||||||

| ACM | AEM | EPDM | FKM | HNBR | NBR | VMQ | ||

| Mineral oils | Oils for motors | +130°C | +130°C | - | +170°C | +130°C | +100°C | +150°C |

| Oils for gearboxes | +120°C | +130°C | - | +150°C | +110°C | +80°C | +130°C | |

| Oils for hypoid gears | +120°C | +130°C | - | +150°C | +110°C | +80°C | - | |

| ATF oils | +120°C | +130°C | - | +170°C | +130°C | +100°C | - | |

| Hydraulic oils | +120°C | +130°C | +150°C | +130°C | +90°C | - | ||

| Greases | - | +130°C | - | - | +100°C | +90°C | - | |

| Fire-resistant fluids |

HFA group - Emulsion with more than 80% water | - | - | - | - | +70°C | +70°C | +60°C |

| HFB group - Opposite solution (water in oil) | - | - | - | - | +70°C | +70°C | +60°C | |

| HFC group - Polymer aqueous solution | - | - | +60°C | - | +70°C | +70°C | - | |

| HFD group - Water-free synthetic fluids | - | - | - | +150°C | - | - | - | |

| Other fluids | EL + L heating oil | - | - | - | - | +100°C | +90°C | - |

| Air | +150°C | +150°C | +150°C | +200°C | +130°C | +90°C | +200°C | |

| Water | - | - | +150°C | +100°C | +100°C | +90°C | - | |

| Water for washing | - | - | +130°C | +100°C | +100°C | +100°C | - | |

| Temperature range | Min. | -25°C | -40°C | -45°C | -20°C | -30°C | -30°C | -60°C |

| Max. | +150°C | +150°C | +150°C | +200°C | +150°C | +100°C | +200°C | |

| Nominal Shaft Diameter | Tolerance |

| up to 4.000 | +/- 0.003 |

| over 4.000 to 6.000 | +/- 0.004 |

| over 6.000 to 10.000 | +/- 0.005 |

| over 10.000 | +/- 0.006 |

| Shaft Material and Hardness | ||

| Condition | Material | Hardness |

| General | Carbon steel(Heat treatment or nitriding is especially recommended) | 45 HRC min. |

| For sealing water with low surface velocity | Stainless steel | 55 HRC min. |

| Bore Tolerance in inches | |

| Bore Diameter | Bore Tolerance |

| up to 3.000 | +/- 0.001 |

| 3.001 to 6.000 | +/- 0.0015 |

| 6.001 to 10.000 | +/- 0.002 |

| 10.001 to 20.000 | +/- 0.002/- 0.004 |

| 20.001 to 40.000 | +/- 0.002/- 0.006 |

| 40.001 to 60.000 | +/- 0.002/- 0.010 |

| Bore I.D. Roughness | Maximum Roughness |

| Metal O.D. | 10 microinches Ra 2.50 microinches Ra |

| Rubber covered O.D. | 150 microinches Ra 3.75 microinches Ra |