Negotiable

The date of payment from buyers deliver within days

Zhejiang

Long-term effective

2017-10-31 08:41

134

Company Profile

Company Profile

By certification [File Integrity]

Contact:Ms. Vivian Xu(Mr.)

Email:

Telephone:

Phone:

Area:Zhejiang

Address:Zhejiang

Website: http://ternalparts.artstx.com/

| Description: | Copper Connector With CNC Turning |

| Application: | Engineering Machinery Parts |

| Material: | HFe59 |

| Part Weight: | 0.1 |

| Process | CNC Turned Machining + CNC Machining Centre |

| Surface Roughness | R1.6 |

| Surface Treatment | None |

| Package: | Polywood Box or Carton Box |

| Lead time for sample: | 25-30 days |

| Delivery time for normal order | 30days |

| Payment Terms | T/T, L/C or negotiation |

| Delivery port departure | Ningbo/Shanghai Port |

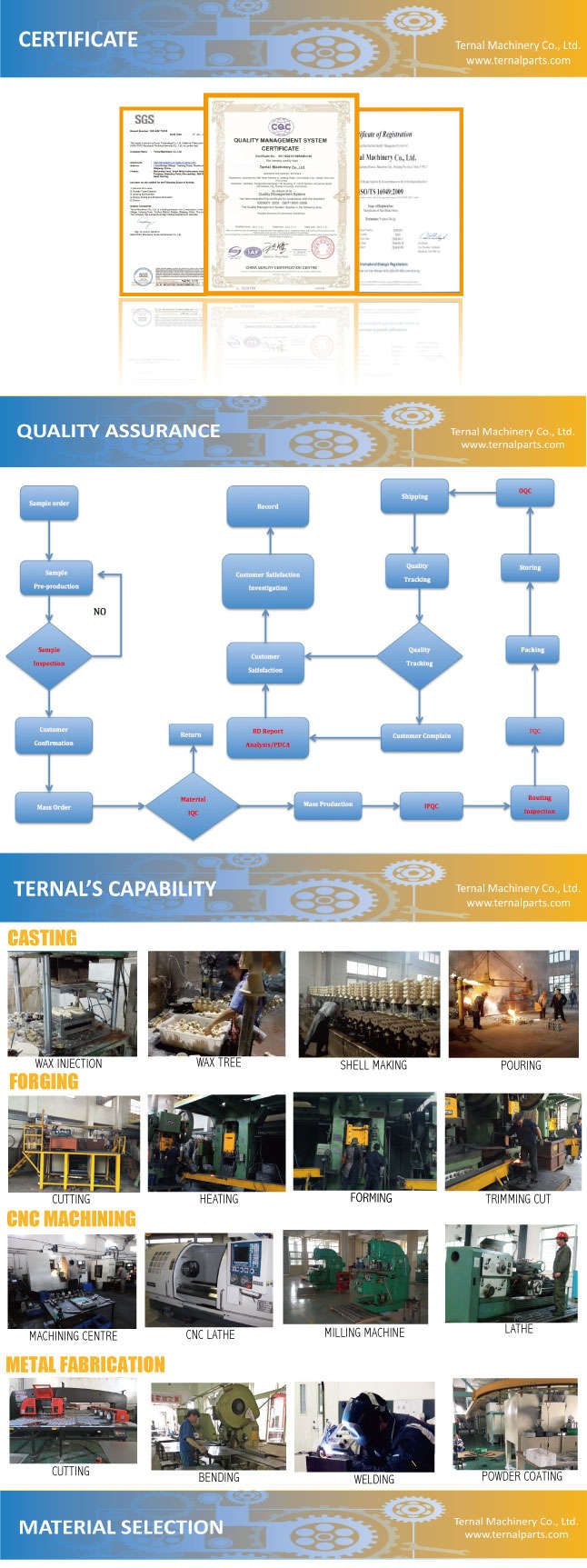

| Process | Material Available |

| Investment Casting | Plain Carbon Steel,Alloy Steel,Stainless Steel |

| Sheet Metal Fabrication | SPCC,SHCC,SECC,SGCC,Cooper,Aluminum Plate,Aluminum Extrusions,Stainless Steel |

| Sand Casting | Steel,Alloy Steel,Gray Iron,Ductile Iron,Aluminum,Cooper |

| Lost Foam Casting | Gray Iron,Ductile Iron |

| Die Casting | Aluminum Alloys,Zinc Alloys |

| Forging | Plain Carbon Steel,Alloy Steel,Stainless Steel,Aluminum,Cooper |

| Stamping | Steel Plate Cold Commercial,Steel Plate Hot Commercial,SPTE,SUS |

| Powder Metallurgy | Iron,Carbon Steel,Cooper Iron,Iron-Nickel,Nickel Steel,Stainless Steel |

| Extrusions | Channel Steel,Square Steel,Round Squarei,U Steel,T Steel |