High Flow Commercial UV Bacteria Treatment Water Purification Systems UV Disinfection

Commercial bacteria & virus water treatment specifically designed to meet the demanding microorganism control requirements in high purity water systems. Typical Industrial disinfection applications include: Dairy, pharmaceutical, electronics, cosmetics, breweries, chemical plants, bottling plants, marine industries, petroleum industries, hospitals, drinking water, textile industry, swimming pools, microelectronics, universities, blood banks, medical centers, cosmetics and food industries, and research industries. Available flow rates from 10 gallons per minute to to 1,000,000 gallons per day

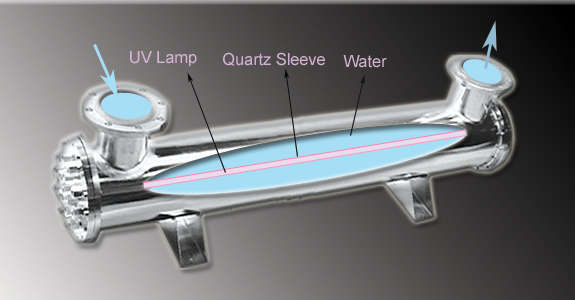

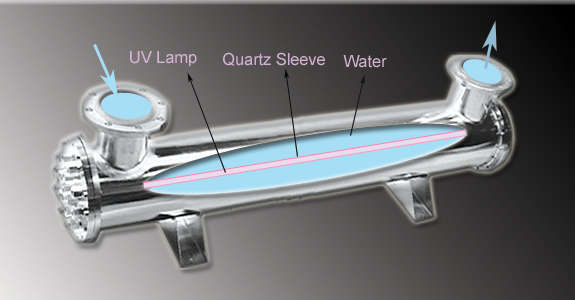

How Ultraviolet Disinfection System Works

As water flows past the UV lamp(s) in a UV disinfection system, microorganisms are exposed to Ultraviolet light energy. Ultraviolet light alters the DNA material in cells so that bacteria, viruses, molds, algae and other microorganisms can no longer reproduce. The microorganisms are considered dead, and the risk of disease from them is eliminated. These Ultraviolet Disinfection Systems are designed for commercial & industrial applications. The process of UV Disinfection is accomplished without adding any harmful chemicals to your drinking water and does not distort the water or effect its pH value. UV Disinfection has an effective kill rate of 99.99% of most living microorganisms such as bacteria & viruses.

UV Disinfection is suitable for Industrial & Commercial

UV Disinfection is suitable for Industrial & Commercial

- Agriculture, Dairy, Livestock, Irrigation Water

- Food & Beverage Industry

- Beer Breweries, Wineries

- Drinking Water

- Ice Companies

- Well Water

- Aquaculture

- Restaurants, Schools, Hospitals, Hotels

Technical parameters:

| model |

Processing capacity (Ton/Hour) |

power (W) |

inlet and outlet

(inch) |

working pressure (Kg/cm 2 ) |

malfunction alert for UV lamp |

reactor dimension (cm) L×W×H |

dimension of panel(cm) |

anchor bolt (cm) |

overall weight (Kg) |

| YLCn-005 |

0.3 |

16 |

1/2" |

6 |

matched |

30×6×11 |

|

|

5 |

| YLCn-008 |

1 |

25 |

1/2" |

6 |

matched |

47×6.3×11 |

|

|

10 |

| YLCn-050 |

2 |

40 |

1" |

6 |

matched |

100×9×20 |

Φ8.9×25

(diameter×length) |

69×4×Φ1 |

25 |

| YLCn-150 |

6 |

80 |

1+1/4" |

6 |

matched |

100×11×23 |

69×4×Φ1 |

30 |

| YLCn-200 |

8 |

120 |

1+1/2" |

6 |

matched |

100×15.9×30 |

Φ8.9×45

(diameter×length) |

69×7×Φ1 |

35 |

| YLCn-300 |

12 |

160 |

2" |

6 |

matched |

100×15.9×32 |

69×7×Φ1 |

40 |

| YLC-050 |

2 |

40 |

DN25/1" |

6 |

matched |

100×8.9×30 |

25×30×12

(L×H×w) |

60×4×Φ1 |

45 |

| YLC-150 |

6 |

80 |

DN32/1 1/4 " |

6 |

matched |

100×10.8×30 |

60×4×Φ1 |

50 |

| YLC-200 |

8 |

120 |

DN40/1 1/2 " |

6 |

matched |

100×15.9×40 |

60×7×Φ1 |

60 |

| YLC-300 |

12 |

160 |

DN50/2" |

6 |

matched |

100×15.9×40 |

60×7×Φ1 |

70 |

| YLC-360 |

15 |

200 |

DN65/2 1/2" |

6 |

matched |

100×15.9×40 |

50×78×25

(L×H×W) |

60×7×Φ1 |

120 |

| YLC-500 |

20 |

240 |

DN65/2 1/2" |

6 |

matched |

100×21.9×50 |

60×11×Φ1.2 |

130 |

| YLC-600 |

25 |

280 |

DN80/3" |

6 |

matched |

100×21.9×50 |

60×11×Φ1.2 |

140 |

| YLC-700 |

30 |

320 |

DN100/4" |

6 |

matched |

100×21.9×50 |

60×11×Φ1.2 |

150 |

| YLC-1000 |

40 |

360 |

DN100/4" |

6 |

matched |

100×21.9×50 |

60×11×Φ1.2 |

160 |

| YLC-1200 |

50 |

400 |

DN125/5" |

6 |

matched |

100×21.9×50 |

60×11×Φ1.2 |

180 |

| YLC-1500 |

60 |

420 |

DN150/6" |

6 |

matched |

170×27.3×57 |

120×16×Φ1.4 |

210 |

| YLC-2000 |

80 |

560 |

DN150/6" |

6 |

matched |

170×27.3×57 |

120×16×Φ1.4 |

220 |

| YLC-2500 |

100 |

700 |

DN150/6" |

6 |

matched |

170×27.3×57 |

60×128×30

(W×H×T)

|

120×16×Φ1.4 |

275 |

| YLC-3000 |

125 |

840 |

DN150/6" |

6 |

matched |

173×27.3×57 |

120×16×Φ1.4 |

300 |

| YLC-4000 |

150 |

1120 |

DN200/8" |

6 |

matched |

173×32.5×65 |

120×20×Φ1.6 |

325 |

| YLC-5000 |

200 |

1400 |

DN200/8" |

6 |

matched |

173×37.7×72 |

120×22×Φ1.6 |

350 |

| YLC-7000 |

300 |

2100 |

DN250/10" |

6 |

matched |

175×42.6×80 |

120×24×Φ2.0 |

400 |

| YLC-10K |

400 |

2520 |

DN250/10" |

6 |

matched |

176×52.9×95 |

60×150×40

(W×H×T) |

120×28×Φ2.2 |

475 |

| YLC-15K |

600 |

3080 |

DN300/12" |

6 |

matched |

176×78×110 |

120×32×Φ2.4 |

600 |

| YLC-20K |

800 |

3920 |

DN350/14" |

6 |

matched |

confirmed |

confirmed |

confirmed |

confirmed |

| YLC-25K |

1000 |

4760 |

DN350/14" |

6 |

matched |

confirmed |

confirmed |

confirmed |

Maintenance requirements for UV units

Lamp Replacement

UV lamps do not burn out as normal florescent lamps do. Instead, the UV lamps will solarize, reducing their intensity to about 60% of a new lamp after about one year of continuous use. When lamps are new, they will generate a dosage level near 60,000 µW-s/cm2 . When the dosage drops to 30,000 µW-s/cm2 (the minimum dosage needed to effectively kill bacteria) lamps should be replaced. Lamp life will be shortened significantly if the lamp is turned on and off more frequently than once every eight hours.

Monitoring Performance

Water should be sampled and tested for bacteria counts regularly. Sample before and after the UV unit to test its performance. Water should also be sampled in the animal rooms since bacteria regrowth can occur downstream of the UV unit.

Cleaning

As water passes through the UV unit, minerals, debris and other material in the water will deposit out and onto the quartz or Teflon sleeve. This will limit the penetration of UV rays through the sleeve and into the water. To maintain high clarity, the glass around the lamp must be cleaned regularly. Cleaning frequency depends on the water quality and will be minimal with RO, distilled, or deionized water.

Monitoring UV Dosage

UV light intensity meters are available which indicate the penetration of UV light through the glass sleeve and the water. Low intensity means the UV dose is too low to provide adequate disinfection. This meter will indicate when cleaning or lamp replacement is needed

FAQ:

Q. Does the water have to sit in the UV sterilizer to be disinfected?

A. No. If the system is sized correctly, the water is disinfected as it flows through.

Q. What if the water flows faster than is allowed through the system?

A. If the flow rate exceeds the design flow rate of the UV sterilizer, then there is a possibility that the water will not be properly disinfected. It is important to use a flow restrictor so that the flow rate cannot be exceeded.

Q. How long does the lamp last?

A. The lamps last approximately 10,000 hours. That is why we recommend replacement approximately every 12 - 14 months of continuous operation. After this period, the lamp itself becomes solarized and blocks the rays form entering the water.

Q. Are these systems bigger energy users?

A. No. The 12 gallon per minute model, for instance uses only 39 watts, about half the amount an ordinary light bulb uses.

Q. My water is sometimes cloudy. Is that a problem?

A. Yes. The water that enters the ultraviolet sterilizer must be absolutely clear and have a turbidity of less than 1 NTU. If your water is cloudy, then it must be pretreated.

Company Profile

Company Profile