Negotiable

The date of payment from buyers deliver within days

Hubei

Long-term effective

2017-12-10 19:29

154

Company Profile

Company Profile

By certification [File Integrity]

Contact:Mr. Yang(Mr.)

Email:

Telephone:

Area:Hubei

Address:Hubei

Website: http://timingcutter.artstx.com/

TIMING Automatic Cutting Machine - machine working video on Youtube

• Automatic cutting machine working theory display : https://youtu.be/Pf_3s5Oa73s

• Automatic cutting machine ( high vacuum level ): https://youtu.be/VHnmd21CNAA

• One to one training for our customer in TIMING factory: https://youtu.be/wFWpIXbxBUE

• Automatic cutting machine for garment industry : https://youtu.be/Yht03YyNQWY

• Automatic cutting machine for car seats : https://youtu.be/Tzc5VcuDHz0

• TIMING cutting software demo : https://youtu.be/HykK9I2SWck https://youtu.be/Bk2N43ZxXeQ

• Single ply cutting machine: https://youtu.be/3QI0Y4R21-w

TIMING company video : https://youtu.be/ywJ46G19zKk

So many materials , so little time

Automatic Cutting Machine for compressed lay thickness up to 50/70/90 mms according to the kind of fabric to be cutted.

Flexible configurations for the optimization of the cutting process, specific configurations for all Indutries and parameter settings customized for each customer. Digital control, intuitive of all functions to best fit the needs of production. Fast, noiseless and precise, make available to the operator all machine functions and therefore also data feed-back in real time. Available in a wide range of useful cutting heights in according to the characteristics required and for configurations of any thickness lay: from single ply up to 9 cm. compressed. Machine eco-friendly thanks to a mentality towards the working environment protection with high power saving.

Model specifications ( Three Standard Sizes ):

Model TMCC-2020 for example :

| Cutting Height | 3cm / 5cm / 7cm / 9cm (after vac-sorb) |

| Cutting Window | length (no limitation) |

| width (no wider than the fabric width) | |

| Working Width (Y) | 2000mm |

| Table Width | 2330mm |

| Norminal Working Length (X) | 2000mm |

| Electricity | Three phase 380V, 50~60Hz |

| Rated Power Consumption | 18kw |

| Cutting way (method) | up and down repeatedly cutting |

| CAD&CAM Connect way | Ethernet communication / USB Flash memory |

| Max speed of blade working | 4000rpm/min |

| Motor driver of CNC system | TECO TAIWAN / PANASCNIC JAPAN (Optional) |

| Motor drive of pneumatic system | SMC JAPAN |

| Deceleration system | Planetary Gear |

| 4 sets servo motor X,Y,Z,T | 400W-2KW |

| Compressed Air | 0.55Mpa 160L/min |

| Cutting Speed | max.60000mm/min |

| Acceleration | 0.6~0.8g (N/ Kg) |

| Noise Level | < 75 dbA |

| Functional Temperature: | -10 ºC- 45ºC |

| Humidity: | 5- 95%, not condensing |

| Machine Dimension | Length/Width/Height(approx.) : 4.93m/ 2.75m/1.5m Weight(approx.): 2200kg |

| Remark:Customization is available. The specification is subject to change without notice. | |

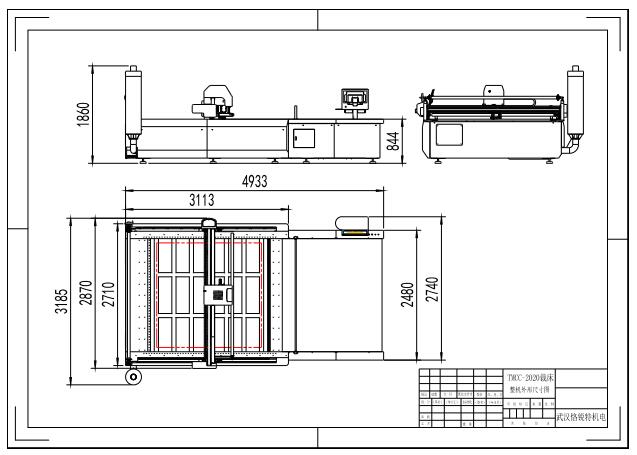

TMCC-2020 dimension

Textile Auto-Cutting Machine

Applicable to lady's fashion, swimsuit, underwear, cap, uniform, suits and jeans, sports wear, knitting wear, automotive seating and interiors, house wear and furniture.

| model | fabric | texture | cutting layers | vac-sorb thickness | cutting efficiency per 8 hours | material features | remark |

| 7CM | high-grade leisure trousers | woven(cotton+ spandex +chemical fiber) |

80 layers | 4CM-4.5CM | 3000 sets | unelastic,less breathable, stiff material |

adults |

| 7CM | uniform(two pieces) | woven(mainly chemical fiber) |

60 layers | 4CM | 1200 sets | Easy to melt,stick knife less breathable,stiff material |

adults |

| 7CM | non-woven fabric | Polyester | 80 layers | 5CM | 5000 sets | stick knife,breathable | garment accessory |

| 7CM | linter(two pieces) | knit(cotton) | 100 layers | 6.8CM | 7000 sets | Elastic,breathable | kids |

| 7CM | bourette | woven(cotton +silk) |

220 layers | 5CM | 15000 sets | unelastic,less breathable,smooth | kids |

| 7CM | jersey | knit(cotton/ polyester) |

130 layers | 6CM | 8000 sets | Elastic,breathable, smooth |

kids |

| 7CM | Polyester | knit(cotton+ polyester) |

110 layers | 6.8CM | 8000 sets | Elastic,breathable, smooth |

adults (sports) |

| 7CM | warm | knit(cotton+ silk floss) |

40 layers | 6.5CM | 2000 sets | Elastic,breathable, thick |

kids |

| 7CM | polar fleece | Polyester | 40 layers | 6.5CM | 3000 sets | Elastic,breathable, thick,wool |

kids |

| 7CM | coral fleece | Polyester | 40 layers | 6.5CM | 3000 sets | Elastic,breathable, thick,wool |

kids |

| 7CM | Woolen cloth fabric | chemical fiber +plush |

50 layers | 5CM | 4000 sets | Elastic,less breathable,thick material,wool | adults |

TIMING , Specialized in flexiable materials cutting solution .

Wuhan Tianming Photoelectric Technology Co., Ltd. actively promotes the integration of industrialization and informatization, technological innovation of electromechanical equipment and popularization of automatic cutting technology, and has a production line integrating laser cutting machine ,CNC cutting machines, intelligent spreading machines, These products are widely used for soft material cutting field in clothing, spinning, leather, automobile, aviation, aerospace, home furnishing and other industries, and help customers increase achievements, efficiency and capacity.

Years of experience and the innovative thinking of the Company make possible a unique standard of rapid and competent customer support and perfect service throughout the world.

1.What languages are supported?

Currently, courses are available in English. Additional languages will be added in the future. If a course in a specific language is desired, please let us know

2.What about the warranty?

12 months from the date of installation.

3.Should I prepare a computer?

We have computer(DELL brand mostly) in package for the cutter, no need to buy computer at your side for the cutter.

4. how could I learn to operate the auto cutter?

There will be training for customers ,the main training contents as follows:

(1) Machine operating procedures training;

(2) Panel and the significance of control parameters, the parameter range of options;

(3)The machine basic cleaning and maintenance;

(4)Common hardware failure treatment;

(5) Some problem of Operation should pay attention

(6) In addition we also provide products processing technical support.