metal roof wall panels machine

Introducation

Machine consist of uncoiler and its base, coil sheet guiding equipment, roll forming system, post cutting equipment, pressing equipment, post-cutting system,hydraulic station, controlling system, supporter table.

Machine Feature:

1.Precise forming

2. High-solid forming stand guarantees the goods and uniform high quality of final product

3. The operation automatically minimizes the tolerance of cutting length

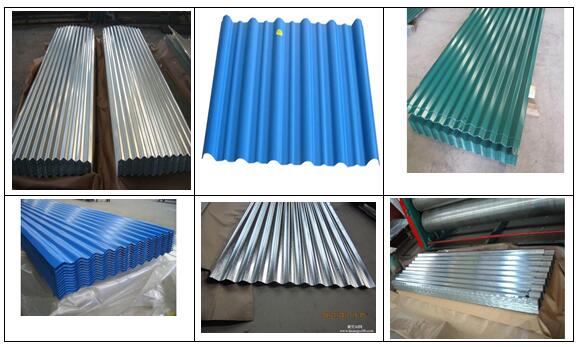

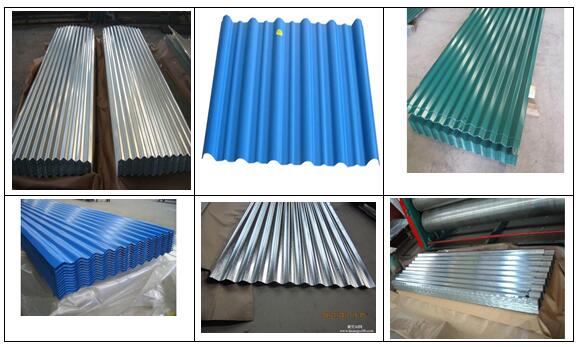

Products Feature:

1. A stylish and attractive design, giving the apperance of a traditional roof tile.

2. Resistant to frost, heat,hail and gale; 100% waterproof, due to the lateral run-off channel on each sheet for several models.

3.The raw material can be in different color, with elegant and noble looking. It is widely used as the garden like factory, hotel, exhibition, villa,civil construction etc.

Product Description

Main parameter of color steel roll forming machine :

No. |

roof sheet making machine |

1 |

Suitable material |

Color steel plate; galvanized steel sheet |

2 |

Width of the plate |

840mm |

3 |

Rollers |

11 rows |

4 |

Dimensions |

5.7*1.45*1.5m |

5 |

Power |

4+4kw |

6 |

Thickness of the plate |

0.3-0.6mm |

7 |

Productivity |

8-10m/min |

8 |

Material of the cutting blade |

Cr12 |

9 |

Diameter of the roller |

Φ75mm |

10 |

Weight |

About 2.8 T |

11 |

Voltage |

380V 50Hz 3phases |

12 |

Control system |

PLC control |

Components and Technical Specification of roof sheet making machine

1. Manual Uncoiler

Usage:It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand.

Loading capacity:5T

Inner diameter: 500-508mm

2. Feeding Table

Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

3. Hydraulic System

Power:4kw,Hydraulic oil: 40#

hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

4.Computer Control Cabinet

The target piece`s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use.

PLC:EURA

5.Cutting System:

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Cr12,quenching treatment

6.Output Table

It adopts welded steel and supported roller to transmit the products,which is used to collect the finished products.

Company Profile

Company Profile